Efficient tool management is important for maintaining productivity and accountability. The tool tracking process involves monitoring tools’ status and whereabouts, ensuring that they are always at hand when needed. In past years, various methods have been used to streamline this process; however, radio frequency identification (RFID) tags have proved themselves as a promising solution. The innovative technology has changed the way of tool tracking and made it more efficient and accurate. In extended reading/writing ranges and reduced reading times, RFID provides greater tool management efficiency, aligning with industry standards 4.0.

In this article, we will discover how RFID technology improves tracking tools, saves costs and increases security, offering an exciting perspective on the future of manufacturing efficiency.

Benefits of Using RFID Tags for Tools

- Reduce the risks for FOD:

Avoiding FOD (damage to foreign objects) is a major manufacturing problem. It is a problem that affects many industries, such as aerospace, construction, retail, and industrial manufacturing. In the field of aerospace, the FOD can cost more than $ 3 billion.

Using RFID tool tracking can help stop FOD. This allows the managers of facilities to monitor all their tools. They can easily prove if a tool is taken and not restored before using the resolved equipment. This will help prevent expensive injuries and keep everything working without problems.

- Efficient inventory management:

RFID technology proves wonders when it comes to administering its inventory. It doesn’t matter if you need to verify what is on your store shelves, follow the development of a product being made, or find out if something needs to be returned to the warehouse. RFID can do this all efficiently.

What’s more good is it can help you save your time and money. Unlike bar codes that require a clear view to scan, RFID labels can be read directly, which means less work and faster results. RFID portable tools also make it a breeze to monitor and audit their genitals since they can scan from different angles, causing the work to work quickly and easily.

- Care of valuable equipment

Your company invest a lot of money in both electrical and hand tools, and these specialized tools are costly. By monitoring RFID tools, you can reduce the possibility of these important possessions being lost, out of place or stolen.

With this, you will not only be able to reduce your company’s everyday expenses but also the overall costs associated with replacing lost or stolen tools. This means that more money stays in your pocket, giving you to invest in other critical aspects of your business. In addition, ensuring that their technicians always have proper tools at their disposal means that they can do their work properly and effectively, ultimately benefiting the productivity and results of their company.

- Take care of your commercial operation:

When the tools are missing, it will slow down the organization and maintenance of your company. These Decelerations can put your business at risk, and you lose a lot of money. But with RFID tool tracking, you can efficiently solve these problems. This helps to ensure that your team will continue to work without problems, avoiding expensive interruptions for your business operations.

- Safety and Security:

Safety is very important to maintain while running any business, and with an RFID tool tracking system, you can maintain a safe and secure workplace. It works like a bodyguard for each tool by keeping a closed eye on them. Thus, it reduces the risk of misuse and keeps each tool organized. With RFID tool tracking, you know which tool is being used, ensuring that only trained individuals handle them. In emergencies, quick access to tools can help you a lot by enhancing overall workplace safety and preparedness.

RFID Tags vs. Traditional Tool Tracking

Traditional Tool Tracking:

- Manual system: the manual system of tracking tools keeps track of tools using handwritten records, which can be slow, susceptible to errors, and challenging in constituencies.

- Bar code: Similar to scanning prices in a store, barcode tools are somehow better than manual systems, but they can still be relatively slow; plus, barcodes may damage or break in sudden or tough conditions.

- GPS tracking: they are like finding a phone using GPS, but GPS tracking is suitable for outdoor use and for larger equipment.

RFID’s benefits to traditional methods:

RFID is like a futuristic update for monitoring tools. It is fast, accurate, and works both indoors and outdoors. This means you can save time, reduce errors and have complete control over your tools, improving overall efficiency and tool management. With RFID, you move from ancient and slow forms to a clever and fast tool monitoring solution.

Why choose RFID tool tracking?

Managing the tool is important for any successful business. It ensures that your entire team can work well and avoid costly mistakes such as losing tools.

However, doing so with old methods, such as bar codes or foam organizers, can be uncomfortable. You will have to give a lot of time to monitor tools, and employees will waste their time finding them. It can cause delays and unhappy customers.

In addition, using traditional methods also causes tools to be out of place or disappear. Finding tools can really be anxious and slow down the process.

The good news is that there is an easy and affordable solution: RFID tool tracking. With this, employees can find tools in seconds and verify them quickly by entering and removing them, making everything easier and better.

What type of tools can be tracked using RFID Asset Management Systems?

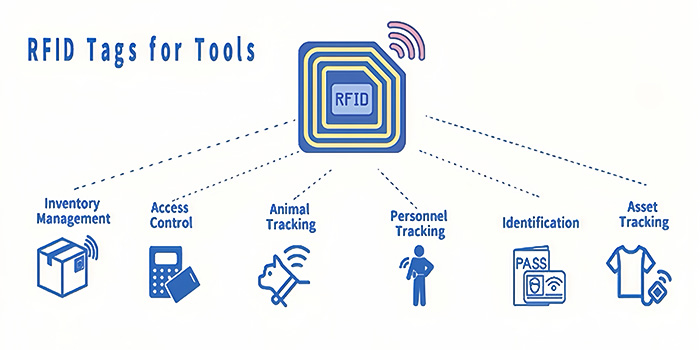

An RFID system is an innovative and versatile technology that helps track all types of tools of your company, such as:

- Forklifts

- Pallets and pallet trucks

- Equipment for handling drums

- Industrial ladders

- Hydraulic stackers

- Reusable bins

- Carts and dollies

- Dock equipment

Whether your business is big or small, you can use RFID to track your tools in any industry. To get the right system for you, consider what kinds of tools you need to keep an eye on and the size of your business. Then, you can pick the system that fits your needs best.